PP/PE Granulation line

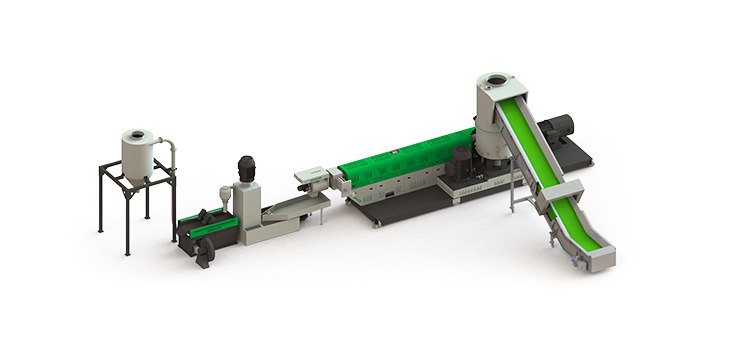

Film Agglomeration and Pelletizing Line-Double Stage

The pelletizing and granulating unit is mainly used to recycle soft plastics with low bulk density, and is suitable for recycling and granulating raw materials such as films, fibers, waste silk, and non-woven fabrics. Adding some auxiliary equipment can also be used for the recycling of hard materials.

Technical parameter

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuun |

Screw Changer |

Water-ring |

Cold Strand |

Underwater |

|

120+120 |

350-400 |

0.2-0.35 |

90-110/22-30 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

|

150+150 |

500-700 |

0.2-0.35 |

132-185/45-55 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

|

180+200 |

750-1200 |

0.2-0.35 |

250-355/90-110 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

|

200+200 |

1200-1500 |

0.2-0.35 |

315-400/110-132 |

28-33/10-12 |

Single/Double |

Option |

Option |

Option |

Option |

Film Agglomeration and Pelletizing Line-Single Stage

The pelletizing and granulating unit is mainly used to recycle clean soft plastics with low bulk density, and is suitable for recycling and granulating raw materials such as films, fibers, waste silk, and non-woven fabrics. Adding some auxiliary equipment can also be used for the recycling of hard materials.

Technical parameter

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuun |

Screw Changer |

Water-ring |

Cold Strand |

Underwater |

|

120 |

350-400 |

0.2-0.35 |

90-110 |

28-36 |

Single/Double |

Option |

Option |

Option |

Option |

|

150 |

500-700 |

0.2-0.35 |

132-185 |

28-36 |

Single/Double |

Option |

Option |

Option |

Option |

|

180 |

800-1200 |

0.2-0.35 |

250-355 |

28-36 |

Single/Double |

Option |

Option |

Option |

Option |

|

200 |

1200-1500 |

0.2-0.35 |

315-400 |

28-36 |

Single/Double |

Optio |

Option |

Option |

Option |

Rigid Flake Pelletizing Line

The production line is suitable for recycling and granulating all kinds of hard miscellaneous materials. It can effectively filter and purify all kinds of plastics, eliminate water vapor, and homogenize them into particles of consistent size.

Technical parameter

Single Stage

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuum |

Water-ring |

ScreenChanger |

Cold Strand |

Underwater |

|

120 |

350-400 |

0.2-0.35 |

90-110 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

|

150 |

500-700 |

0.2-0.35 |

132-185 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

|

180 |

700-1200 |

0.2-0.35 |

185-355 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

|

200 |

800-1500 |

0.2-0.35 |

200-400 |

30-33 |

Single/Double |

Option |

Option |

Option |

Option |

Double Stage

|

Model |

Output |

Energy Consumption |

Main Power |

L/D |

Vacuum |

Water-ring |

ScreenChanger |

Cold Strand |

Underwater |

|

120+120 |

350-400 |

0.2-0.35 |

90-110/22-30 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

|

150+150 |

500-600 |

0.2-0.35 |

132-185/45-55 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

|

180+200 |

700-1200 |

0.2-0.35 |

185-355/90-110 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |

|

200+200 |

800-1500 |

0.2-0.35 |

200-400/110-132 |

30-33/10-12 |

Single/Double |

Standard |

Option |

Option |

Option |