Wholesale Dealers of Mb Feeder - PP Meltblown Fabric Production Line – Grace

Wholesale Dealers of Mb Feeder - PP Meltblown Fabric Production Line – Grace Detail:

While the global epidemic is still not effectively controlled, as the world’s leading manufacturer of extrusion equipment, Grace takes full advantage of its extensive experience and leading technology in the extrusion production industry, developing a new generation of PP Melt-blown Fabric Production Line.

As the main raw material for the production of high-quality medical/civilian masks, protective clothing and other medical materials, the market still has a huge demand for melt-blown fabric, especially when various countries start to produce medical materials on their own, the supply of melt-blown fabric will be huge challenge.

Therefore, Grace Melt-blown Fabric Production Line designed with high efficiency, stability and energy saving will be your best investment choice!

Value advantage

Melt-blown cloth uses high-speed hot air flow to draw the thin stream of polymer melt extruded from the orifice of the die, thereby forming ultra-fine fibers and collecting them on the mesh curtain or drum, and at the same time bonding themselves to become Melt-blown non-woven fabric.

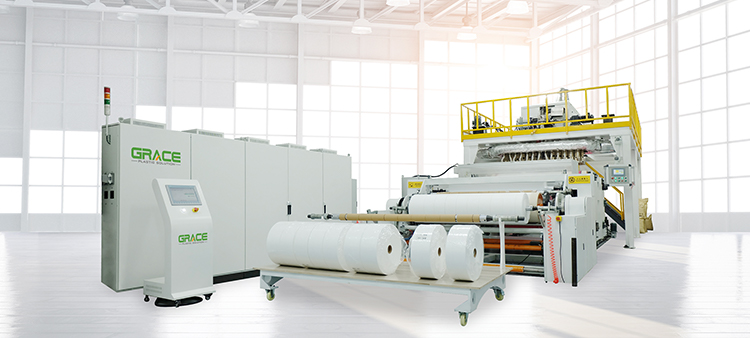

GRACE MACHINERY600mm/1600mm PP Meltblown Fabric Production Line The Whole Process of PP Melt-blown Fabric Production Line:

Raw materials and energy consumption required for each ton of melt-blown fabric production

Raw materials required per one million disposable face masks (tons)

Professional and master production:

A new generation of 99+ grade PP meltblown fabric production line

European standard extruder design: Brand of drive and gearbox: siemens; Melt pump: swiss maag.

High quality die head: excellent flow channel design and uniform discharge, the fiber diameter is below 1.5um.

Siemens PLC centralized control system: Intelligent and more convenient. Electrostaic stationary pole.

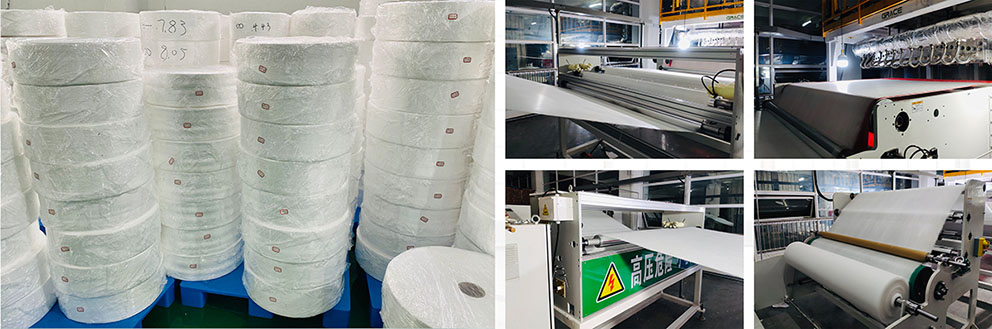

Successful Projects

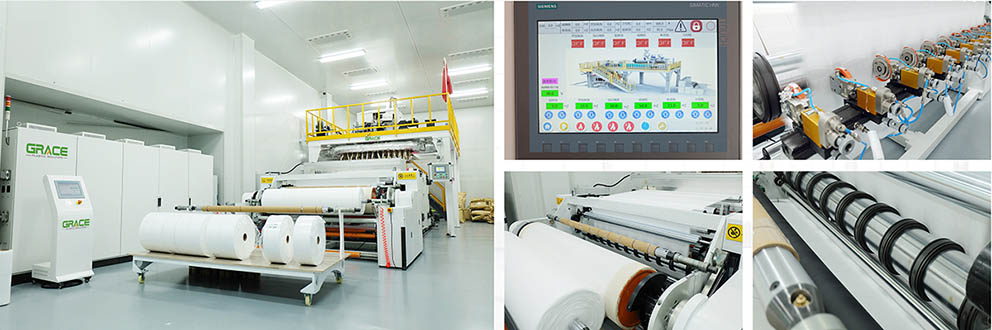

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Wholesale Dealers of Mb Feeder - PP Meltblown Fabric Production Line – Grace , The product will supply to all over the world, such as: Guinea, Monaco, Guyana, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.